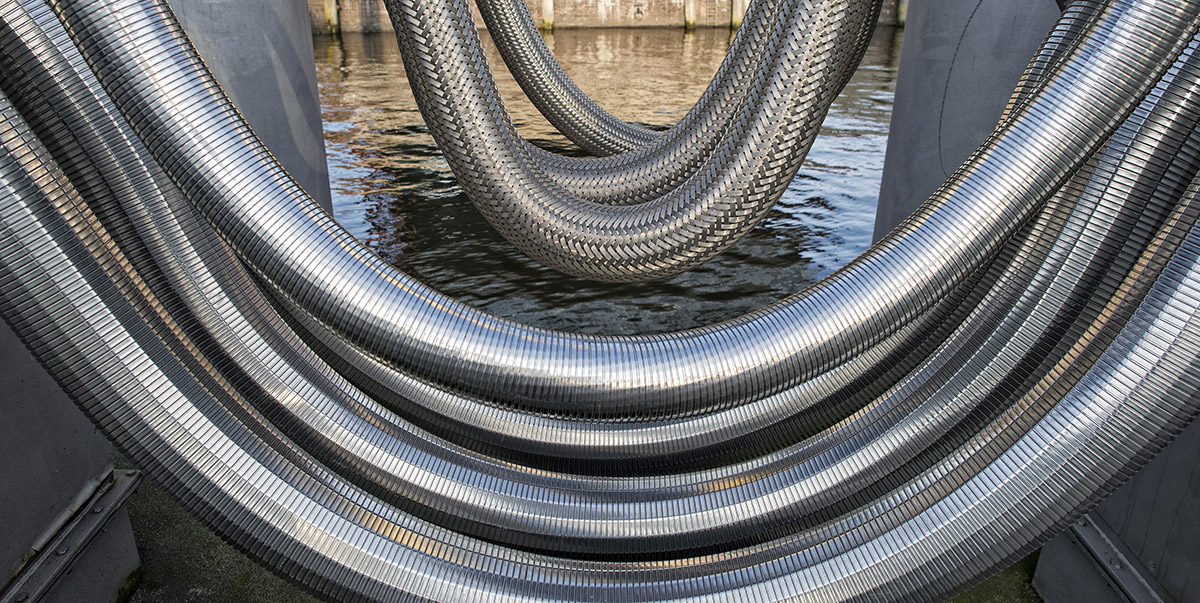

Stainless Steel Convoluted Hose

Hoseworx provides an extensive range of Stainless steel corrugated hoses.

All stainless steel corrugated hoses are manufactured to ISO10380 standards, from butt welded stainless steel tube and are hydraulically formed into annular corrugations.

Convoluted Hose Industry Applications

- Pulp/Paper Mills

- Steam

- Industrial Gas

- Steel Manufacturing

- LNG / CSG

- Water Treatment / Desalination

Hoseworx range of corrugated tube is manufactured from SS316L with SS304 braid as standard, however we can manufacture hoses in different grade combinations including SS321.

It can be used unbraided for low pressure or vacuum applications or with single or double layers of braid added to increase pressure and abrasion resistance as well as the elimination of vibration.

Available in a variety of alloys and in sizes ranging from 6mm up to 350mm with an endless combination of end fittings.

About Currugated Metal Hose

Corrugated metal hose is constructed from various grades and thickness of Austenitic cold formed stainless steel. Rolled and butt welded into tube, It is then hydraulically formed into Parallel corrugations, which are evenly spaced along the entire length of the hose.

The Profile, material, wall thickness, depth and spacing of the corrugations, determines the flexibility, application and pressure rating of the hose.

Hoseworx range of corrugated metal hose is available in 3 different profiles depending on the application.

These profiles include;

- GenFlex - Annular Corrugations which are evenly spaced - good flexibility and cycle life at medium pressures.

- BendFlex – Annular Corrugations which are closely spaced / close pitch ‘tear drop’ shaped highest flexibility and cycle life at medium pressures.

- UltraFlex- Annular Corrugations which are evenly spaced and formed from heavy wall butt welded tube- good flexibility at high pressures.

Depending on the pressure, the hose assembly is manufactured with one or two layers of stainless steel woven braid. The braid is applied tightly to the hose and TIG welded to the end fittings, by AS1796 qualified staff. The braid not only resists pressure, it prevent elongation (expansion of the hose through internal pressure) and protects the exterior of the hose.

Convoluted Hose Protective Options

There are many protection options which can be fitted to help prolong the life of your hose assembly and reducing the risk the operator. Protection may be required against extreme temperature, dragging, excessive user bending, careless handling, etc.

Below are some of the options available, if the protection you would like is not listed, please contact our sales team.

Spring Guard

Fitted to the hose during manufacture, and fixed to the ends by welding. This spring forms a barrier between the hose and any rough surface the hose may be exposed to. Available in galvanised and stainless steel, in standard pitch and with close pitch ends – which offer excellent protection to the ends of the hose.

Abrasion Sleeve

This nylon woven abrasive sleeve is fitted to the hose after manufacture and fixed to the ends by crimping or heat shrink. This sleeve is used in applications where hoses may be exposed to damage by rubbing. Also used as burst suppression, creating a barrier between medium and personnel (Not suitable for cryogenic applications).

Plastic Spiral Guard

Fitted to the hose after manufacture, by wrapping around the hose. This plastic wrapping has excellent abrasion and crush resistance. Also helps to prevent over bending and kinking. Commonly used on delivery hoses due to its light weight and high protection properties (Not suitable for cryogenic applications).

Interlock Guard

Stainless steel interlock hose can not only be used inside the hose to create a smooth bore and reduce velocity, but it can be used on the outside as a excellent form of protection. Its thick and durable stainless steel construction makes it ideal for the most demanding applications. Commonly used for cryogenic delivery assemblies.

Silicone Fibreglass Sleeve

![]()

Manufactured In accordance with AS1072, this silicone coated, fibreglass braided sleeve is designed to protect the hose against exposure from fire/flame, exhaust, steam and even molten metals- up to1200°c. Also used to protect users from handling while hot. Fixed to the hose after manufacture using crimp rings (Not suitable for cryogenic applications).

Technical Aspects of Corrugated Hose

Hoseworx range of corrugated hose is manufactured in accordance with ISO 10380. Hoses are manufactured with a 4:1 safety factor for example the burst pressure is 4 times the maximum working pressure. The hose test pressure is 1.5 times the maximum working pressure. Various operating conditions affect the service life and pressure resistance of corrugated hose such as:

Temperature

The working pressure of corrugated hose is calculated at 20°c, as the temperature of the hose increases, the working pressure is reduced. The reduction in pressure can be calculated, using the temperature correctional factor chart, which is located on the data specification sheet.

Pressure

Pressure Loss - when installed in a piping system, pressure is lost due to the corrugations of the hose causing friction with the medium, reducing the flow rate. This problem can be alleviated by increasing the diameter of the hose. The Operating pressure of the hose determines the service life (lifetime of the hose) this can also be affected by the following:

- Pressure Fluctuations - Pressure surge is a sudden increase in pressure, which causes the hose to violently shake which fatigues the corrugations, leading to premature failure.

- Pressure Pulsing - where the pressure of the hose constantly rises and reduces, also fatigues the corrugations and leads to premature hose failure.

Mechanical

- Torsion - Corrugated hoses have high pressure and temperature resistance, however, they have no torsion strength. Twisting a corrugated hose will lead to premature failure almost immediately.

- Bending – Corrugated hoses are highly flexible, however, bending the hose beyond the nominated dynamic bend radius causes the hose to heavily fatigue and prematurely failure. Using elbows as opposed to bending the hose will increase the service life of the hose.

- Velocity – excessive medium flow rates causes a vortex effect inside the hose. This is due to friction between the corrugations and the medium. This problem can be alleviated by including a PTFE or Interlock liner inside the hose.

All Hoses are manufactured in accordance with ISO10380 and AS4041 to customer specifiactions. All hoses are tested and certified before dispatch. Many methods of testing are available such as Hydrostatic, Pneumatic, Vacuum and dye penetrant. Other finishing options include Oxygen cleaning, nitrogen packing and many more.

Hoseworx will custom make stainless steel convoluted hoses to your specifications

Advantages of using Stainless steel convoluted hose

- Temperature range of -270°c up to 750°c

- High Chemical resistance

- No gas permeation

- High strength

- Vibration elimination